This is what greets me. No fuel pressure. I quickly check for spark, injector pulse, and scantool communication. I have everything except for fuel pressure. Now it is time to figure out why. I do not want to disturb anything like connections or relays. So, I head for the inertia switch in the right side kick panel. With that exposed I can use my low amp probe to check the health of the fuel pump circuit and the fuel pump itself.

So, with everything hooked up I crank the engine over and take a snapshot of the scope pattern. The advantages of the low amp probe are many. I like it because it is quick and non-intrusive. Lets look at that pattern.

I get a non modulating 18 amp pattern. This is typical of a fuel pump that is locked up. High amperage with no humps. One thing I can take from this pattern is the circuit is in good shape or else we wouldn't be able to support almost 18 amps of current. Now, there is a caveat here. Be sure to inspect the wiring around the top of the tank and framerail before fingering the pump. So what can we do to also confirm our findings?

We go low tech! A quick wrap on the tank with a rubber mallet is usually enough to vibrate the pump enough to unlock. So I smack and retry. Here is the scopeshot.

Now that is ugly! A couple of more whacks and I get this.

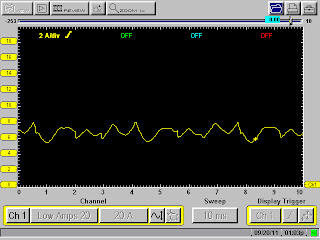

The truck roars to life and this fuel pump sounds like a jet engine. Lets check our running pattern.

Amperage is a bit high at 8 amps peak. I usually see 6 amps or so. The pattern is terrible. This pump has seen better days for sure. I wouldn't be taking this truck too far. I report my findings to the shop owner. He calls the customer and explains the issue and gives an estimate. Customer refuses the job. Oh well, I hope he is handy with a rubber mallet. Here is an example of a good fuel pump pattern for comparison.