This is a nice 2005 GMC Yukon with 156K miles on it, I am asked to look at on this nice and sunny morning. The customer complaint is that the Service Engine Soon lamp illuminates. I start the truck up and it runs quite well and the lamp is not on presently. I scan for current codes and get none. Scanning for history codes I get a P0171 (System lean bank 1), P0174 (System lean bank 2), and a P0101 (Mass Air Flow Performance). Now at this point most techs would say put a mass air flow sensor in it and send it on it's way. I need to be absolutely sure before I stick my neck out. So many factors could cause these codes from weak fuel pumps to glitchy connections at the mass air flow sensor to damaged air filters causing turbulence that would affect the mass air flow sensors calculations. So the first thing I do is a visual. You never know what you are going to find with your eyes.

Nothing amiss here. I check the air filter for fit and function as well as the air ducting. All seems to be in good working order. The mass air flow sensor is installed correctly as well. There are certain GM applications where the mass air flow can be installed incorrectly. There are arrows on the sensor indicating flow direction. I also look to see if there are any aftermarket air flow ducting, air filters, etc and make notes of it. It wouldn't be the first time I have seen the $450.00 chrome billet air flow tube that was supposed to give you 65 more horsepower causing issues such as this. Alright time to look at some scan data. These new generation GM V-8 motors have had their fair share of intake manifiold gasket issues. Looking at fuel trims at an idle and raced up show some pretty tight fuel control. Plus, looking at some freeze frame and failure records show me these codes set at mid range rpm's with the engine fully warmed up. Typical intake manifold gasket issues rear their heads more at low speeds and low engine temperatures.

Time to take a test drive. If you have been following my blog you know that I have been beating up my new scanner the Ottotest pretty bad. I decided to use it on this vehicle because of it's excellent graphing capabilities.

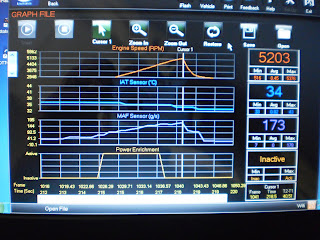

The above is part of a graph I did on the road test. Remember, click on the pics to enlarge. I graphed mass air flow sensor grams per second, short term fuel trims for both banks, and power enrichment mode. I took actual photos of these screen shots for two reasons. One, I wanted to show you the multi colored graph which is very cool. The second is that when you save the graph on Ottotest to export, it is a xps file that is black and white. Something I hope they fix. Saving it on the Ottotest retains the color, you can also scroll after the fact, as well as play with the cursors. The above screen shot is meant to show you the relationship betwen air flow and short term fuel trim. The actual numbers on the right reflect cursor 1, which isn't even on any event in this field so diregard for right now. Here is another screenshot below.

Do you notice something yet? Short term fuel trims follow air flow. When air flow increases fuel trims increase. It may be hard to see due to the graph scaling. In the above screenshot the cursor is on this screen and on frame 792, so the numbers on the right are correct. Let's zoom in and recheck something the Ottotest does really well.

Now it becomes more apparent. remember this is a normal test drive. Whenever, you have fuel trims following air flow you have an air measuring error. Remember, that an air measuring error is conditional on proper air ducting, filtration, etc. Now what? Do we call a bad mass air flow sensor? Not yet. I always like to do a couple of wide open throttle runs at speed and record some parameters to calculate volumetric efficiency. So changing my parameters to graph. I go with engine rpm, mass air flow sensor g/s, intake air temperature, and power enrichment.

Here is a screen shot of a wot (wide open throttle event). Remember, the cursor is all the way at an idle event see the rpm and low g/s. I wanted to illustrate a full from idle to wot event. I always get asked what is a good g/s reading at an idle? At wot? Well, there are no hardfast rules but g/s at an idle should equal your liter displacement on anything over 2.5 liters. Wot readings should be your liter dispacement times 40 as a general rule. This 6.0 liter had a value of 7-8 g/s at an idle. Lets look at some more data.

To figure out VE (Volumetric Efficiency) you need these parameters and use your highest g/s reading. Here I snuck up on it with my cursor. Given our rule of thumb is this reading low or correct for this vehicle? Looks a bit low since we should be seeing close to 240 g/s at wide open throttle. But, lets let the VE calculator be the judge. You can find VE calculator downloads all over-some free-some not. Let's do some calculations.

Engine Size (Cid)-366.15

Engine Rpm-5048

G/S-178

Intake Air Temp (F)-96.8

Volumetric Efficiency-61.667%

A good VE for a naturally aspirated engine is 80% or better. Any type of forced induction should net you 100% or better. We are well below our 80% goal at 61.667%. Let's see what happens when we add our theoretical proper g/s value.

Engine Size (Cid)-366.15

Engine Rpm-5048

G/S-240

Intake Air Temp (F)-96.8

Volumetric Efficiency-83.146%

So, there may be some truth in that value. I always take a couple of wot runs and check a bunch of them. Here is another.

I will zoom in....

Behold, the power of graphing! On the road test the vehicle definitely didn't have the power a 6.0 liter should have and detonated quite badly. I graphed the o2 sensors on wot runs as well just to make sure I wasn't also running out of fuel. They were definitely showing enrichment. Now, I could have gone further and done a low amp probe on the fuel pump circuit as well as fuel pressure and volume tests. But, given the data I had with the customers complaint I was sure we had a bad mass air flow sensor. The detonation is coming from an improper timing schedule due to the under reporting mass air flow sensor. Typically, this is how a mass air flow sensor will fail. It will report correctly at an idle and under report as airflow increases. This is not always the case though. You can have any combination for failure. Oh, by the way I do not agree with cleaning mass air flow sensors to fix them. Cleaning to verify you are going in the right direction-yes. The reason for my thinking is simple. Once you clean that customers mass air flow sensor and it takes care of his problem they are going to think a MAF cleaning is going to fix any issue from check engine lamp to rear brake noise. I report my findings to the shop owner and move on to the next vehicle.